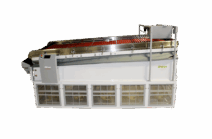

Gravity Separator

What is a Gravity Separator?

Gravity separators is a type of dry separation machinery used for the seed cleaning equipment, industrial food processing equipment, and industrial recycling equipment industries. They can process a complex mixture of dry materials and separate the different individual particles depending on their density, resulting in a continuous gradation across a range of different densities. Seed gravity separators are also commonly referred to as gravity tables density separators, and air tables.

All food processing machinery products offered at Oliver Manufacturing are backed by 90 years of knowledge and experience to handle any seed, nut, coffee, recycling, lumber, industrial applications, and mining industry separating needs.

All of our Gravity Tables, Destoners, and seed grinding machine products are designed to use air to stratify products into various layers according to their density. Through conveyance on our decks, the products layers are separated from one another by allowing the heavier material to travel up the tilted deck, while at the same time the light material moves down. In almost all cases, a product that has similar shape or color can be separated by using this process.

Oliver knows and understands the weight of decisions like these require time and research to find the best food processing equipment supplier that is fit for your needs. Allow us to prove to you what our top of the line machines and customer service can do for you. We offer product testing at our location in La Junta Co and will be available to test your samples ASAP. After this has taken place we can find the best product from our lines that will suit your needs. Visit our Prove It page to learn more about this process and schedule a free consultation.

-

Flag Gates & Industrial Magnetic Fraction Dividers

Read more -

Maxi Cap Platinum

Read more -

Maxi Cap Gravity

Read more -

Voyager Gravity Separator

Read more -

Hi-Cap Gravity

Read more -

Laboratory Hi-Cap Gravity Separator

Read more

Gravity Separators Uses

While they are most often used for seed and grain operations, seed gravity separators, or gravity table separators, have a variety of applications. Olivers separators can be used to separate sand, beans, coal, cork, chemicals, and other dry materials in bulk. They’re an essential piece of equipment for any industry that processes a lot of dry materials every day.

How Oliver Manufacturing Gravity Separators Work

Oliver Manufacturing’s gravity separator machines, commonly called Oliver gravity tables, divide heavier particles of material from lighter particles differing in their specific densities. On gravity separators, lighter particles are moved upward through the fluidized bed, and heavier particles sink downward. This air essentially makes the particles weigh themselves. The deck itself is tilted uphill and quickly shifting in a perpendicular eccentric motion. This allows the lighter particles to flow over the top of the heavier particles to the bottom of the deck while heavier particles are driven up and over the top. This process allows our gravity separators to separate both light and heavy contaminants from a product simultaneously.

The air, eccentric motion, deck tilt, end raise, and feed rate on an Oliver gravity separator are easily modified and can retain adjustment settings for multiple products. Adjustments to the air, motion, and tilt affect the quality of the separation, while the end raises, and feed rate affects capacity.

Oliver Manufacturing – Almost a Century of Innovation

For nearly a century, Oliver Manufacturing has led the way as a gravity separator manufacturer with high-quality products that businesses in the seed, nut, coffee, lumber, recycling, and mining industries can rely on. We’ve always been committed to combining durability and efficiency in our equipment, and these gravity separators are no different. Contact us today to learn more about how these machines can save you time and money!