Why should you upgrade your MaxiCap?

We understand the need for your equipment to adapt and keep up with the demands of your production. That’s why we have added expanded control capabilities with the Automation Retrofit Kit for the Oliver MaxiCap, offering essential manufacturing automation info to enhance your operations.

Want equipment adjustments done faster?

New digital control settings mean that anyone quickly switches to their favorite settings with the swipe of a finger, integrating manufacturing automation info seamlessly. No more hassle having to spend countless hours training new employees on the minute adjustments.

Have a problem with a part or the computer interface?

The automation refit kit installs remote support capabilities. A simple call or email to our support team enables our technicians to diagnose and repair most issues from our Colorado headquarters.

Need to restore full-working capacity quickly?

The Oliver MaxiCap, with manufacturing automation info provided by the automation retrofit, cuts down labor costs with digital maintenance, diagnostics, and remote help. One call or email to our support teams minimizes downtime and restores your machines to full working capacity—often with no expensive site visits.

The ROI on this investment is fantastic. You will earn back the cost of this upgrade by ‘taking out the trash’ seeds from your crop, reducing downtime, and staying in front of maintenance concerns before they become costly problems. This update is what you need to edge above your competition and take the next step in taking your Oliver MaxiCap control to the next level.

What’s in the refit?

Oliver’s factory automation retrofit kit introduces full automation for all aspects of gravity table adjustment, operation and cleanout. The integration of programmable logic circuitry (PLC’s) and electronic control / hydraulic sensors add both precision and repeatability over separator input parameters:

- Air control

- Table tilt

- Eccentric vibration

- Feed rate

The upgrade kit- which can usually be installed onsite in a matter of days – provides measurable improvements in consistency and performance, and is compatible with most plant-wide integrated processing scenarios.

- Centralized Touchscreen and Joystick control

- Menu driven direct numerical input and memorized ‘recipe’ retrieval

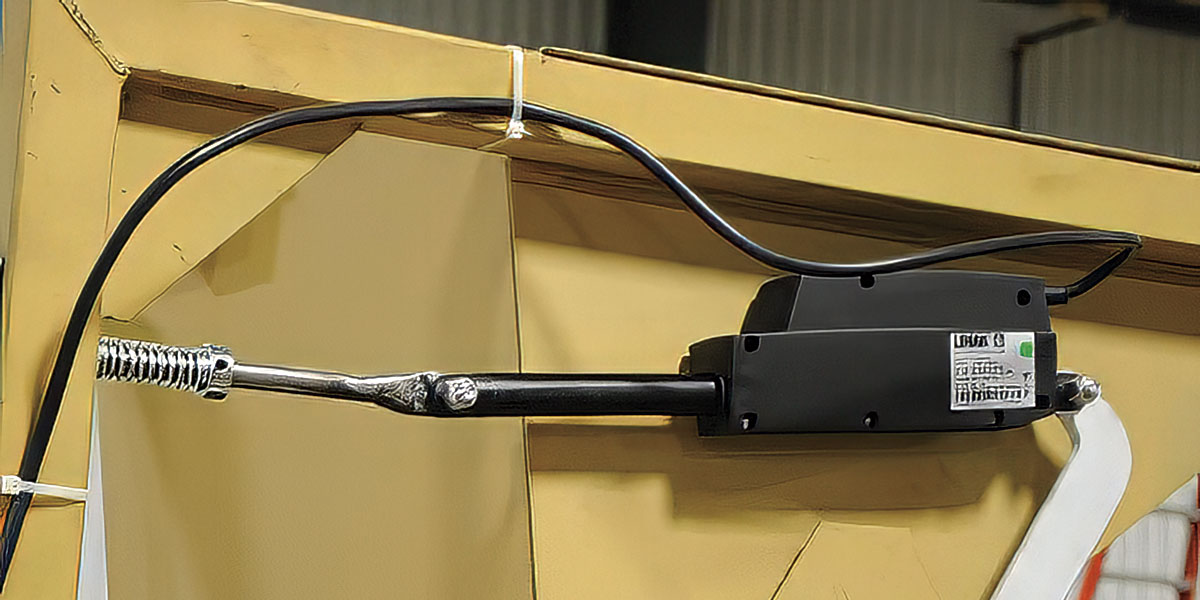

- Digital Electric Control Actuation, for easier setup and repeatability

- Digital readouts

- Pre-stored recipes for setup and cleanout

Setup accuracy is so high that machines installed in parallel for shared streams in higher volume installations can perform identical separations simply by duplicating the settings between machines. Installation can be accomplished by Oliver technicians, through your Oliver Distributor, or by your own qualified in-house maintenance or fabrication staff. Applies to Maxi-Cap Gravity Separator models 2400, 3000, 3600 and 4800.

Want to know more or have questions?

Call us at (719) 254-7813 or send us an email with the button below.