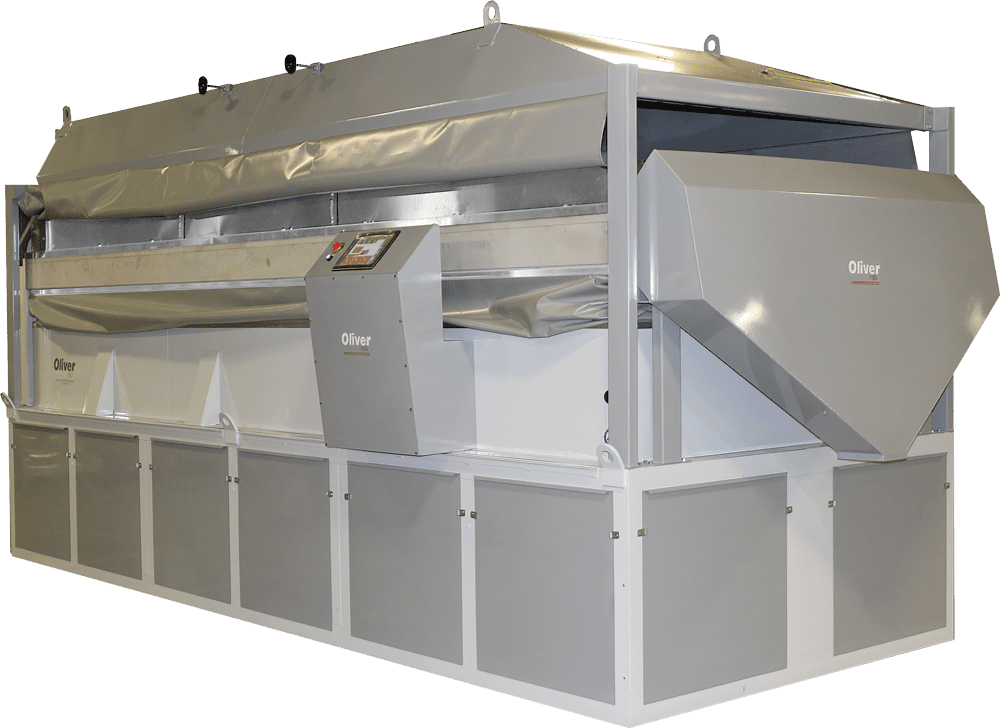

Oliver DVX Vibrating Fluidized Bed Dryers are a deluxe version of our legendary dryers. Complete with the bells and whistles like touch screen control panels and automation, the DVX series prevents product clumping, simplifies cleanup, and improves the finished appearance of seed coatings and treatments. And all while cutting dry time! This fluid bed dryer machine is a revolutionary solution to the frustrations of clumping and bridging treated seeds and edibles. The vibrating fluid bed dryer uses a combination of air in motion through a vibrating, tilted table. Seed flow is converted to a “fluidized” suspension, making gentle, uniform drying possible for coated, treated, or washed seeds.

Models: DVX 304, DVX 307, DVX 410, DVX 512, DVX 616