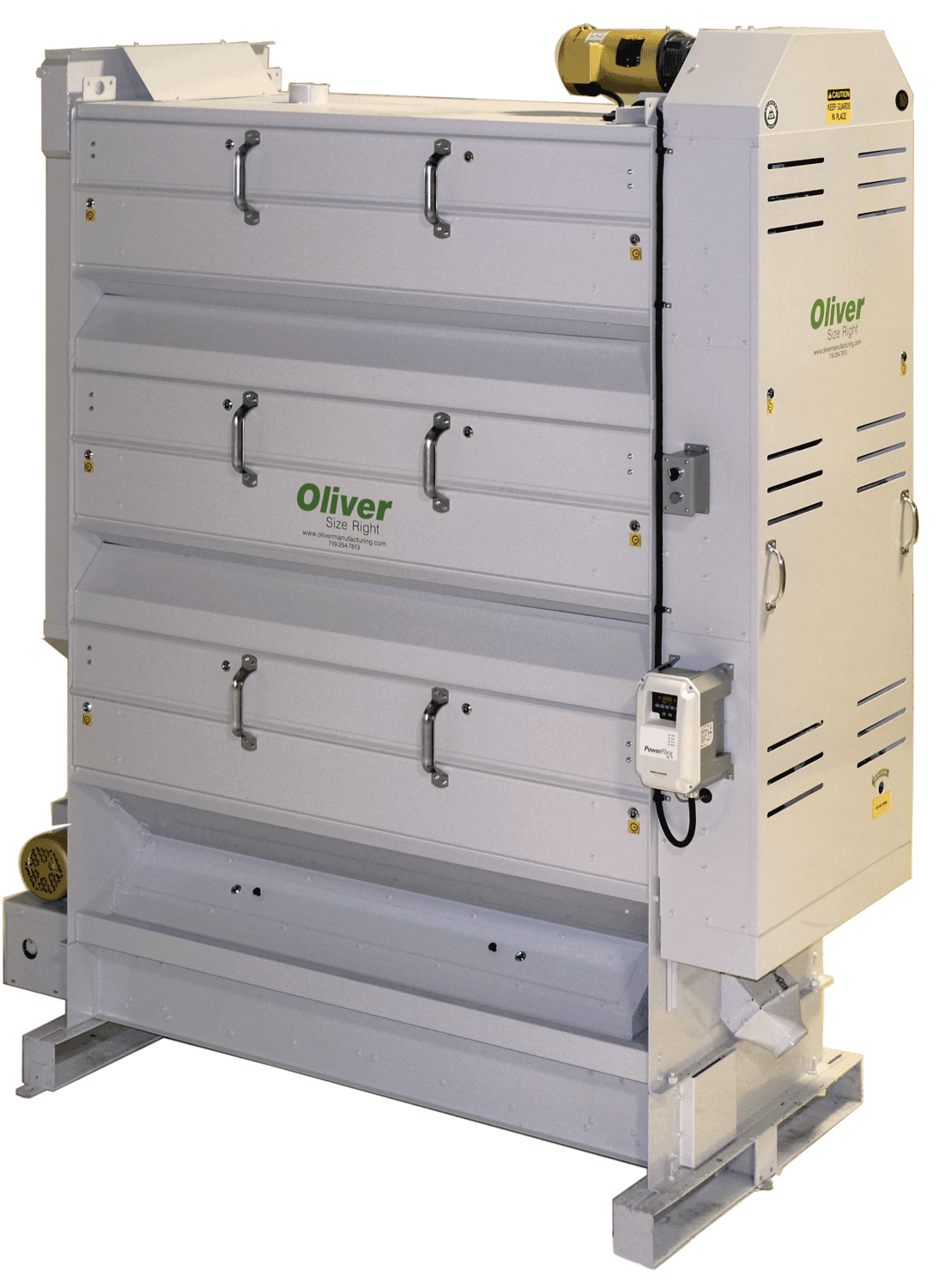

Oliver’s SIZE RIGHT® Precision Cylinder Sizer separates products by width and thickness down to the most accurate screen tolerances in the industry – between +.0003″ and -0.003″. These include some screens that will have four sizes within a 64th (Example 8/64ths, 8.25/64ths, 8.5/64ths, 8.75/64ths, 9/64ths). All precision sizer components on the SIZE RIGHT are heavy-duty and long-lasting, and cylinders are custom-made for all types of precision sorting.

The Size Right® 2 precision sizer is designed to accurately separate materials based on their width and thickness, ensuring optimal uniformity in seed, grain, and industrial processing applications. By using rotating cylinders with precisely engineered indentations, this machine effectively sorts products into specified size categories, improving quality control and downstream processing efficiency. Whether used for agricultural commodities like wheat, corn, and soybeans or industrial materials such as plastic pellets, the Size Right® 2 enhances consistency by removing oversized or undersized particles. This level of precision is critical for seed conditioning, where uniform sizing impacts planting efficiency and crop yield. Additionally, the machine’s adjustable settings allow for customization based on material characteristics, maximizing throughput while minimizing loss. Built for durability and ease of operation, the Size Right® 2 helps processors maintain high-quality standards, reduce waste, and improve overall productivity, making it an essential component in any advanced sorting and grading system.